WP4: Removing micropollutants with aquaporin-based biomimetic membranes

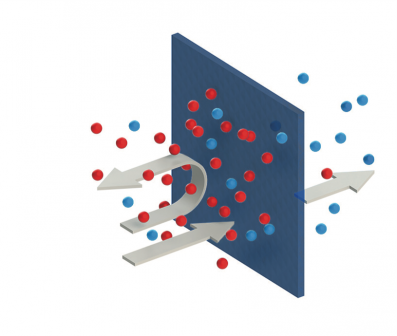

Large volumes of polluted municipal wastewater display a need for installing treatment systems with large footprints. Moreover, operating them requires higher micro-pollutant removal rates and vast amounts of energy. Biomimetic aquaporin-based forward osmosis (FO) membranes have been shown effective to separate micro-pollutants from water using model solutions and small membrane samples.

Large volumes of polluted municipal wastewater display a need for installing treatment systems with large footprints. Moreover, operating them requires higher micro-pollutant removal rates and vast amounts of energy. Biomimetic aquaporin-based forward osmosis (FO) membranes have been shown effective to separate micro-pollutants from water using model solutions and small membrane samples.

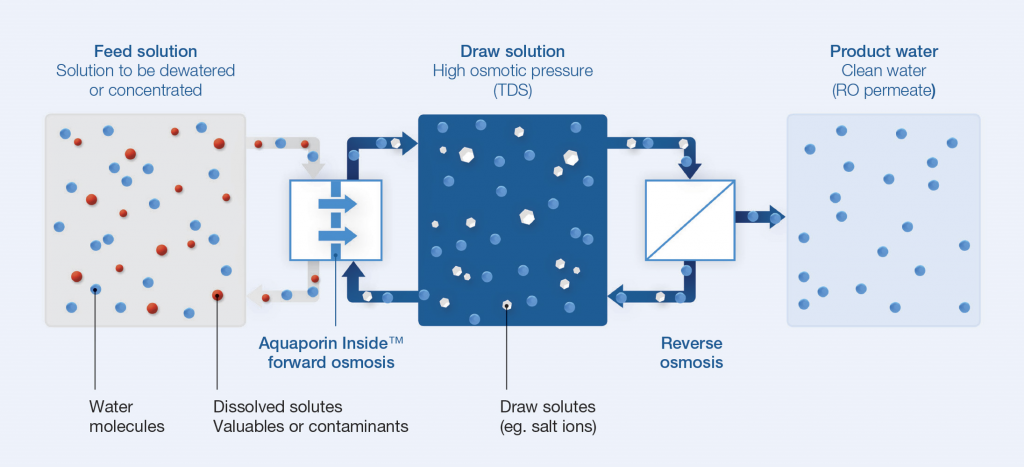

The FO process utilizes the highly selective membranes for concentrating micro-pollutants before a more compact treatment, and is driven by an osmotic pressure gradient across the membrane. The technology can bring energy cost savings thanks to its lack of need for hydraulic pressure.

Objectives

Aquaporin InsideTM Forward Osmosis membranes are highly selective to micropollutants thus the aim is to explore and develop a full process to concentrate municipal wastewater effluent and produce a micro-pollutants-free effluent.

Tasks

Firstly, test the feasibility of a direct Forward Osmosis (FO) process by utilizing the osmotic pressure of plentily available seawater. Secondly, combine Forward Osmosis (FO) with high pressure Reverse Osmosis (RO) to a so-called hybrid process and determine performance of the system in the long-term treating real municipal wastewater effluent from a ceramic MBR system. Maximize performance by optimizing the system’s process conditions. Furthermore, test the the cleaning requirements for the biomimetic membranes utilized in a a such system.

Concept of a hybrid FO-RO process

First results

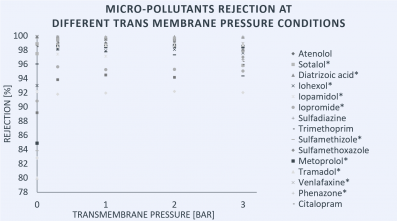

Effect of TMP on rejection of 21 micro-pollutants (14.0 % analytical error), *minimum rejections are based on limit of detection (n=3)

Micro-pollutants rejection of 2.3 m2 hollow fiber FO membranes was tested at different feed and draw flow conditions, as well as different transmembrane pressure (TMP) conditions. Except clarithromycin, all compounds were rejected at minimum 92%.

Similar rejections were measured for the experiments with different feed and draw velocities. Increased draw velocity and TMP both improved water flux, and increased TMP lowered specific reverse salt flux.

The rejection is not observed to be significantly affected by varying TMP up to 3 bar.

Goals

- Assess performance of a full FO-RO-based process at pilot scale

- Assess potential of seawater as a FO draw solution

- Test robustness of FO membranes during long-term operation

FO-RO Pilot Plant

FO-RO Pilot Plant

The pilot plant is located at BIOFOS Wastewater Treatment Plant, Avedøre, Copenhagen, Denmark.

Contact information

Key person

Sylvie Braekevelt, Aquaporin

WP-leader

Prof. Kai Bester, Aarhus University, kb@envs.au.dk

Other participants

Johan Le Nepvou, DTU

Jörg Vogel, Aquaporin

Ulla E. Bollmann, AU

Arthur Mielczarek, Biofos

Project Coordinator

Prof. Kai Bester, kb@envs.au.dk Aarhus University, Dep. of Environ. Sci., Frederiksborgvej 399, DK-4000 Roskilde